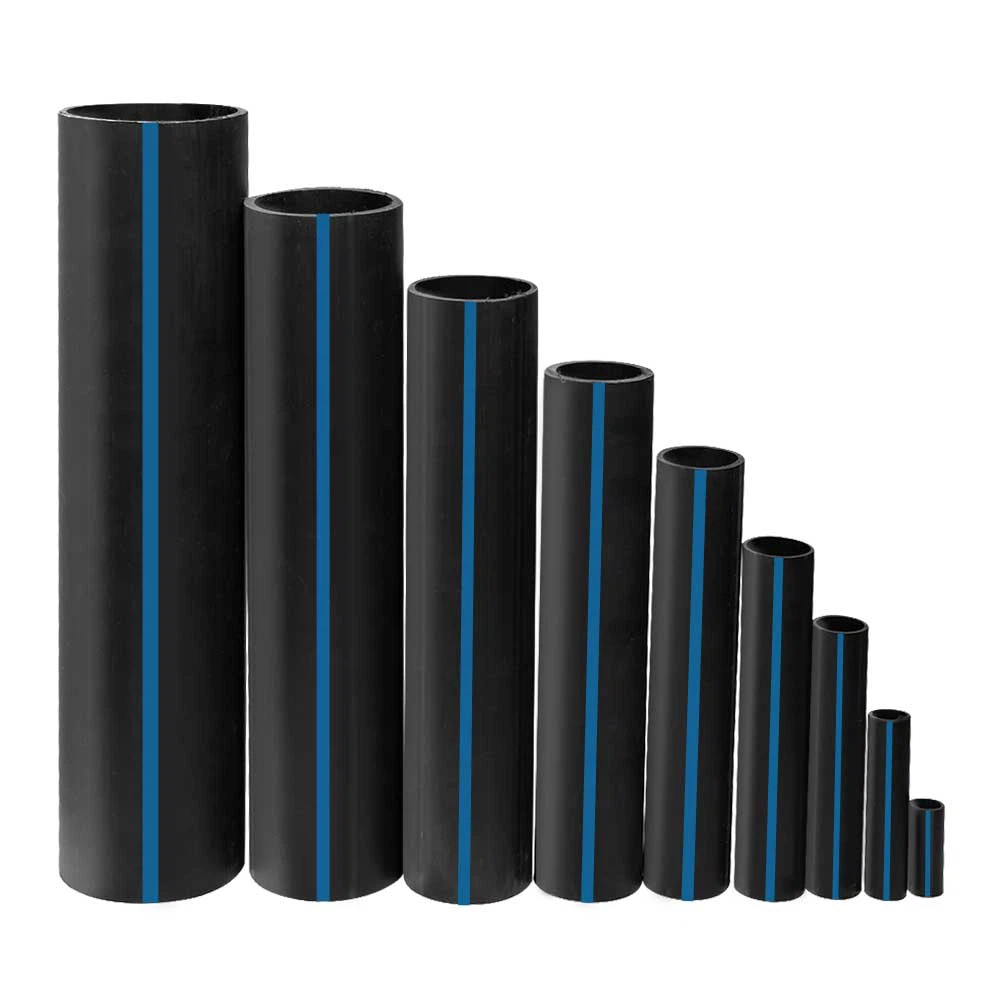

| APPLICATION | STANDARD | CLASSIFICATION | COLOR & STRIPS |

|---|---|---|---|

| Water | EN 12201/ISO 4427 | PE-80 | Fully Blue Color, Black With Blue Strip |

| PE-100 | Fully Dark Blue Color, Black With Dark Blue Strip | ||

| Sewerage | EN 13244 | PE-80 | Fully Brown Color, Black With Brown Strip |

| PE-100 | Fully Brown Color, Black With Brown Strip | ||

| Gas | EN 1555/ISO 4437 | PE-80 | Fully Yellow Color, Black With Yellow Strip |

| PE-100 | Full Color Yellow Orange, Black With Yellow Orange Strip |

| SDR-11 | SDR-13.6 | SDR-17 | SDR-21 | |||

|---|---|---|---|---|---|---|

| Dimension Ratio | PN-16 | PN-12.5 | PN-10 | PN-08 | ||

| Working Pressure (Bar) | Minimum Wall | Standard | Maximum | |||

| Outer Diameter (mm) | Thickness (mm) | Length (m) | Length (mm) | |||

| 20 | 1.9 | 1.8 | – | – | 100 | 1000 |

| 25 | 2.3 | 1.9 | 1.8 | – | 100 | 1000 |

| 32 | 2.9 | 2.4 | 1.9 | – | 100 | 1000 |

| 40 | 3.7 | 3.0 | 2.4 | 1.9 | 100 | 1000 |

| 50 | 4.6 | 3.7 | 3.0 | 2.4 | 100 | 500 |

| 63 | 5.8 | 4.7 | 3.8 | 3.0 | 100 | 250 |

| 75 | 6.8 | 5.6 | 4.5 | 3.6 | 100 | 250 |

| 90 | 8.2 | 6.7 | 5.4 | 4.3 | 100 | 250 |

| 110 | 10.0 | 8.1 | 6.6 | 5.3 | 12 | 12 |

| 125 | 11.4 | 9.2 | 7.4 | 6.0 | 12 | 12 |

| 160 | 14.6 | 11.8 | 9.5 | 7.7 | 12 | 12 |

| 180 | 16.4 | 13.3 | 10.7 | 8.6 | 12 | 12 |

| 200 | 18.2 | 14.7 | 11.9 | 9.6 | 12 | 12 |

| 225 | 20.5 | 16.6 | 13.4 | 10.8 | 12 | 12 |

| 250 | 22.7 | 18.4 | 14.8 | 11.9 | 12 | 12 |

| 280 | 25.4 | 20.6 | 16.6 | 13.4 | 12 | 12 |

| 315 | 28.6 | 23.2 | 18.7 | 15.0 | 12 | 12 |

| 355 | 32.2 | 26.1 | 21.1 | 16.9 | 12 | 12 |

| 400 | 36.3 | 29.4 | 23.7 | 19.1 | 12 | 12 |

| 450 | 40.9 | 33.1 | 26.7 | 21.5 | 12 | 12 |

| 500 | 45.4 | 36.8 | 29.7 | 23.7 | 12 | 12 |

| 560 | 50.8 | 41.2 | 33.2 | 26.7 | 12 | 12 |

| 630 | 57.2 | 46.3 | 37.4 | 30.0 | 12 | 12 |

| 710 | 64.5 | 52.2 | 42.1 | 33.9 | 12 | 12 |

| 800 | 72.7 | 58.8 | 47.4 | 38.1 | 12 | 12 |

| 900 | 81.8 | 66.1 | 53.3 | 42.9 | 12 | 12 |

| 1000 | – | – | 59.3 | 47.7 | 12 | 12 |

| 1200 | – | – | 70.6 | 57.2 | 12 | 12 |

Established in 2019, the factory produces a wide range of pipes for water supply, sewerage, & irrigation, meeting international standards and custom client requirements. It also offers complete pipe-laying solutions with skilled manpower and modern equipment.